Features

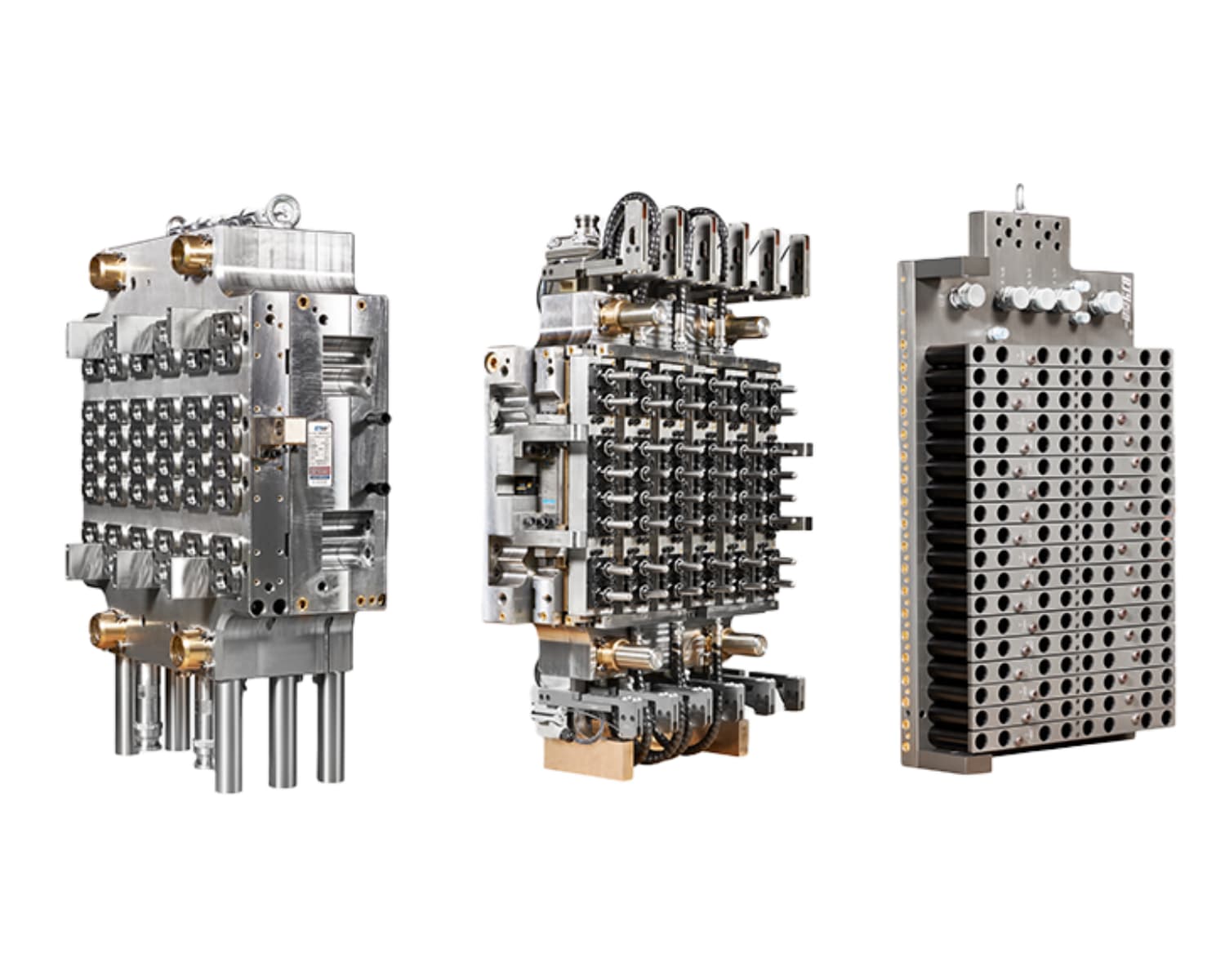

Core Technology: Utilizes ultra-high-precision machining to ensure cavity consistency and preform quality.

High Precision: Machining accuracy within ±0.005mm, surface roughness ≤Ra0.2μm for smooth preforms.

Durability: Cavity/core made of high-grade alloy steel , heat-treated to HRC52-56 hardness for extended lifespan.

Structural Innovation: Optimized mold base design reduces cycle time and boosts efficiency.

Materials & Process: High-wear-resistant materials with EDM & CNC machining for precision.

Customized Service: Supports cavity count, neck finish (e.g., PCO 1881), and other adjustments.

Applications: Suitable for water bottles, carbonated drinks, edible oil PET preforms, etc.

Quality Assurance: Strict inspection protocols, including trial molding reports and full dimensional checks.

Compatibility: Designed for Huayan Injection Machines.

High Efficiency: 48 cavities, cycle time ≤15 seconds, increasing output by 30%+.

Quality Assurance: Mold base flatness ≤0.02mm, minimizing flash and defects.

Mold Structure: Three-plate design with auto-ejection for reduced manual handling.

Energy-Saving Design: Hot runner temperature control ±1°C, reducing energy use by ~20% .

Ultra-High Precision: Cavity tolerance ±0.005mm for uniform preform wall thickness.

High-Temperature Resistance: Sustains 200°C+ injection temperatures .

Custom Service: Adjustable neck finishes (e.g., PCO 1881, 1810) and cavity count.